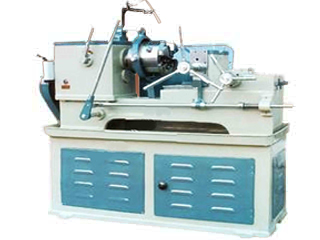

Pipe Threading Machine

Pipe Threading Machine

is used for Cutting External Thread on component

by Chasing method. HSS Tangential Chasers are used as cutters.

Component

remains stationery and Die Head rotates. Matric, BSP, BSPT, NPT,

UNF,UNC, BSW, Acme Threads B.S.F etc. threads can be cut on this

machine depending upon the type of Chasers. The machine mainly consists

the following:-

Pipe Threading Machine

is used for Cutting External Thread on component

by Chasing method. HSS Tangential Chasers are used as cutters.

Component

remains stationery and Die Head rotates. Matric, BSP, BSPT, NPT,

UNF,UNC, BSW, Acme Threads B.S.F etc. threads can be cut on this

machine depending upon the type of Chasers. The machine mainly consists

the following:-PIPE THREADING MACHINES are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with COMPANY TRADITION.

DESIGN &

WORKMANSHIP: The TRUE WORKS MACHINERY & TOOLS,

thread cutting machines are designed to produce quality threads within the tolerance

for which they were intended.

HEAD STOCK:

A heavy duty geared Head Box is of best quality casting providing

support to the spindle bearings. The box is of gear type, lubricated,

fitted with three extra heavy duty bearings.

THE BED:

The bed is pillar type having two pillars made of best

quality steel

nicely finished & duly hard chrome plated in the most modern

hard chrome plating unit.

THE SADDLE:

The Saddle is fitted on two pillars very precisely. It runs on pillars

very smoothly and accurately to the Head Stock alignment.

THE APRON:The apron

gives movement to the saddle with head transfer along with

pillars through steel rack and pinion arrangements. It's all gears are

made of best quality steel.

VICE JAWS:

The vice jaws made from the best quality alloy steel are fitted on the

saddle well aligned with the head stock center fitted in a heavy duty

box type vice. The jaws are heat treated. The movements of jaws are

controlled by a screw on the saddle.

Specification

| Model | 1/4"

to 1" (Bed Type) |

3/8"

to 1.1/2" (Bed Type) |

1/2"

to 2.1/2" (Bed type) |

1"

to

4" (Pillar Type) |

| Saddle Movement | 10" | 10" - 12" | 12" - 16" | 10" - 12" |

| Spindle Speed Range | 60-90 | 60-90 | 60-90-120 | 40-75-115 |

| Number of Spindle Speed | 2 | 2 | 3 | 3 |

| Capacity | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" | 1" to 4" |

| Production per Hour | 60-80 | 60-80 | 70-90 | 35-40 |

| H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. | 12.5 H.P. 960 |

| Lead Screw | Optional | Optional | Optional | Provided |

| Weight (KG) Aprox. | 500 | 550 | 990 | 1600 |